Views: 0 Author: Site Editor Publish Time: 2025-07-06 Origin: Site

Maritime safety and operational efficiency rely heavily on the right choice of marine fenders. Marine fenders serve as critical protective devices that absorb impact energy during vessel berthing, preventing damage to both the ships and port infrastructure. However, marine fenders come in various types, each designed to suit specific conditions, vessel types, and operational requirements. Understanding the different types of marine fenders is essential for ship operators, port authorities, and maritime engineers who seek to maximize safety and minimize costs.

Hongruntong, a leading global supplier of marine products since 1990, offers a diverse range of high-quality marine fenders tailored for commercial ports, naval bases, offshore platforms, and underwater docking stations. This article introduces the main types of marine fenders, explains their features and advantages, and provides guidance on how to select the appropriate type for your maritime projects.

Marine fenders play a fundamental role in maritime operations by acting as cushions between vessels and docking structures. Their primary function is to absorb kinetic energy and reduce collision forces during berthing, thus protecting the integrity of ship hulls and quay walls. Choosing the correct type of marine fender is not a trivial decision. The safety of the vessel, the durability of port infrastructure, and the cost-effectiveness of maintenance and repairs all depend on this choice.

Different marine fender types are engineered to handle specific loads, water conditions, and vessel characteristics. An unsuitable fender can fail to provide adequate protection, resulting in costly damages, downtime, and safety hazards. Therefore, a clear understanding of the types of marine fenders and their operational benefits can help maritime professionals make informed decisions that enhance overall port safety and efficiency.

Pneumatic fenders, sometimes known as Yokohama fenders, are inflatable devices made with a durable rubber outer skin that encases an internal air chamber. This construction allows the fender to deform elastically under pressure, absorbing and dispersing energy during impact. The air chamber provides buoyancy, enabling pneumatic fenders to float on water surfaces and adjust to changing tides and vessel movements.

One of the most significant advantages of pneumatic fenders is their ability to absorb very high amounts of energy with relatively low reaction forces on the vessel’s hull. This balance is critical when berthing large vessels, as it prevents excessive stress and potential structural damage to the ship. Pneumatic fenders effectively mitigate harsh impacts during ship-to-ship transfers and ship-to-dock berthings, where dynamic movements are common.

Thanks to their floating nature and flexible deformation, pneumatic fenders are widely used in commercial ports, offshore oil platforms, and shipyards. Their versatility makes them suitable for ship-to-ship transfers, where vessels need to safely come alongside each other, as well as for berthing against docks and quay walls in fluctuating water levels and wave conditions.

Hydro pneumatic fenders are specialized fenders designed to maintain vertical stability underwater, an essential feature for berthing submarines and underwater vessels. Unlike traditional fenders, they combine an inflatable pneumatic structure with a hydrostatic system that balances the fender’s position underwater. This design prevents the fender from tilting or drifting away from the submarine hull during docking.

Submarine berthing is a complex operation where vessels dock underwater. Protecting the delicate and sensitive submarine hull from impact damage requires a fender that can absorb energy while staying precisely aligned vertically. Hydro pneumatic fenders fulfill this requirement perfectly, ensuring safe mooring at naval bases, underwater docks, and maintenance stations without compromising the vessel’s structural integrity.

Foam-filled fenders are constructed with a closed-cell foam core enclosed within a tough polyurethane outer skin. This sealed foam core prevents water absorption, ensuring the fender remains buoyant and structurally sound over time. The polyurethane skin offers excellent resistance to abrasion, chemicals, and harsh marine environments.

Due to their closed-cell foam core, foam-filled fenders are inherently unsinkable and require no inflation or air maintenance. They are designed to withstand prolonged exposure to seawater and heavy usage without losing performance. These qualities make foam-filled fenders ideal for long-term, maintenance-free applications in ports, offshore platforms, and heavy-duty berthing scenarios.

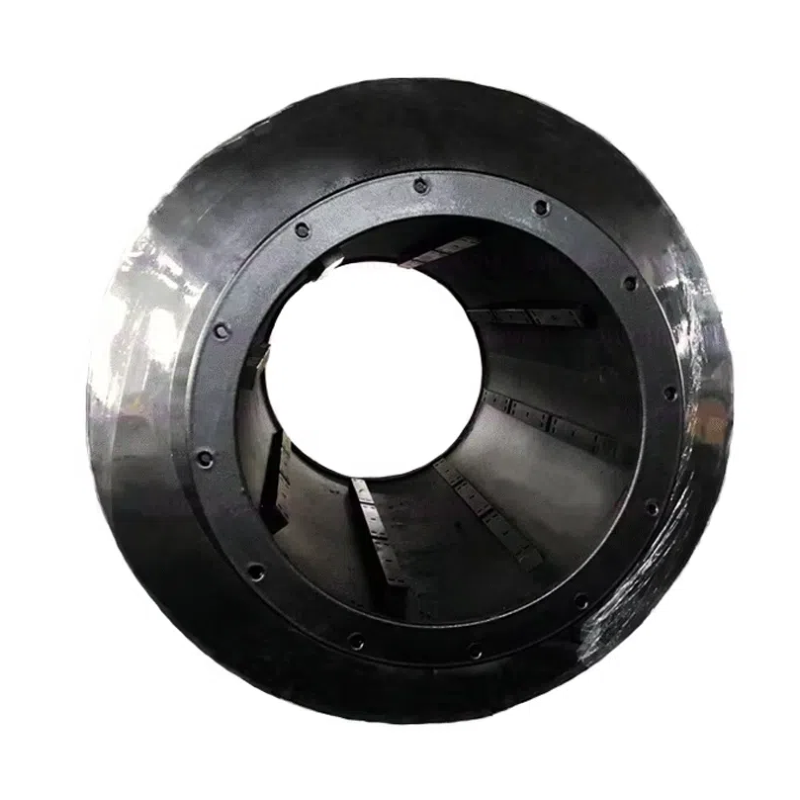

Donut fenders are ring-shaped marine fenders that are mounted around dock piles or cylindrical structures. Their unique circular design allows them to rotate freely around the pile, adapting dynamically to tidal movements and vessel impacts. This rotation capability ensures uniform protection around the entire circumference of the pile.

Piles in tidal zones are vulnerable to concentrated impacts from docking vessels. Donut fenders absorb these forces evenly by rotating and following the natural tide changes, reducing localized wear and structural damage. This feature significantly extends the service life of both the dock piles and the fenders themselves, lowering repair costs and downtime.

Selecting the right marine fender type involves assessing vessel types, operational conditions, and environmental factors. Pneumatic fenders offer excellent versatility and high energy absorption for ship-to-ship and ship-to-dock operations with dynamic water levels. Hydro pneumatic fenders provide the precision and vertical stability needed for safe submarine berthing underwater. Foam-filled fenders deliver durable, maintenance-free protection ideal for heavy-duty and long-term applications. Donut fenders provide specialized 360-degree pile protection, adjusting seamlessly to tidal movements.

For safe, efficient, and cost-effective maritime operations, choosing the right marine fender is a critical investment. Hongruntong offers a wide range of premium marine fenders designed to meet the stringent ISO 17357 and PIANC standards, backed by decades of expertise and global service support.

Contact us today to discuss your specific needs and receive expert guidance on selecting the best marine fender solution for your maritime project.

content is empty!