Views: 0 Author: Site Editor Publish Time: 2026-02-09 Origin: Site

Have you ever wondered how to keep your dock safe from damage? Proper dock protection is crucial for ensuring the longevity of your marine structures.

In this guide, we’ll explore the importance of understanding impact zones and the strategic placement of fenders.

You’ll learn how to effectively safeguard your dock and vessels, ensuring a smooth docking experience every time. Join us as we dive into the ultimate strategies for dock protection!

Dock protection is not just a precaution; it's a vital investment for any marine operation. The risks associated with docking can lead to significant damage, both to the vessels and the infrastructure. Understanding these risks helps in implementing effective strategies for dock protection.

When vessels approach a dock, several factors can contribute to potential damage:

● Impact Damage: Collisions during docking can cause serious harm. The force exerted can lead to hull breaches or structural damage to the dock itself. For instance, a study found that 30% of marine accidents are linked to docking mishaps.

● Environmental Factors: Wind, currents, and tides can complicate docking. Strong winds can push vessels off course, increasing the likelihood of collisions. Similarly, tidal changes can alter the docking environment, making it crucial to have adaptive protection measures in place.

● Neglected Maintenance: Fenders and other protective equipment require regular inspection and maintenance. If not maintained, they can fail when needed most, leading to costly repairs and downtime.

The financial consequences of poor dock protection can be staggering. Here are a few key points to consider:

● Repair Costs: Damage to vessels or docks can lead to expensive repairs. For example, a single incident might cost thousands of dollars in repairs, not to mention the potential loss of business during downtime.

● Insurance Premiums: Frequent claims due to docking incidents can increase insurance premiums. Insurers may view poor dock protection as a higher risk, leading to increased costs for businesses.

● Operational Delays: When accidents occur, operations can come to a halt. Delays in loading or unloading cargo can disrupt supply chains, affecting overall business efficiency.

Incident Type | Average Repair Cost | Potential Downtime |

Minor Hull Damage | $5,000 | 1-2 days |

Major Hull Breach | $50,000 | 1-2 weeks |

Dock Structural Damage | $20,000 | 1 week |

Having a robust dock protection system in place can mitigate these risks. Companies like HONGRUNTONG offer a range of fender types designed to absorb impacts effectively and protect both vessels and docks from damage.

Investing in quality dock protection systems not only safeguards your assets but also enhances operational efficiency. It’s about creating a safe environment for vessels to dock, minimizing risks, and ultimately protecting your bottom line.

Understanding impact zones is essential for effective dock protection. These zones are specific areas on a dock where vessels are most likely to make contact. Identifying them helps in selecting the right fenders and implementing robust protection strategies.

Impact zones refer to areas on the dock that experience the greatest stress during docking. They are critical points where collisions can occur, leading to potential damage. Properly identifying these zones allows for targeted protection measures.

Importance of Identifying Impact Zones:

● Damage Prevention: Knowing where impacts are likely helps in placing fenders effectively.

● Cost Efficiency: Targeted protection reduces the need for extensive repairs.

● Safety Assurance: Minimizing risks enhances safety for both vessels and dock personnel.

The bow impact zone is where the front of the vessel comes into contact with the dock. This area is crucial because it often bears the brunt of the impact during docking.

● Description and Significance: The bow is typically the first point of contact, making it vulnerable to damage. Collisions can cause significant structural issues if not properly managed.

● Recommended Fender Types:

○ HONGRUNTONG Cone Fenders are ideal for this zone. They provide stability under angular loads, absorbing impacts effectively and ensuring the safety of both the vessel and the dock.

The midship area is arguably the most critical for protection. This section of the vessel is large and can exert considerable force against the dock.

● Overview of Critical Area: The sides of the vessel are often exposed to lateral forces during docking, making them susceptible to damage.

● Suggested Fender Solutions:

○ HONGRUNTONG Element Fenders are highly recommended here. They offer high energy absorption, making them suitable for the midship impact zone.

The stern impact zone is where the rear of the vessel meets the dock. This area also faces significant risks during docking, especially when maneuvering.

● Vulnerabilities: The stern can be vulnerable to collisions, particularly when vessels are backing in or out. Damage here can affect the vessel's functionality.

● Recommended Fender Placements:

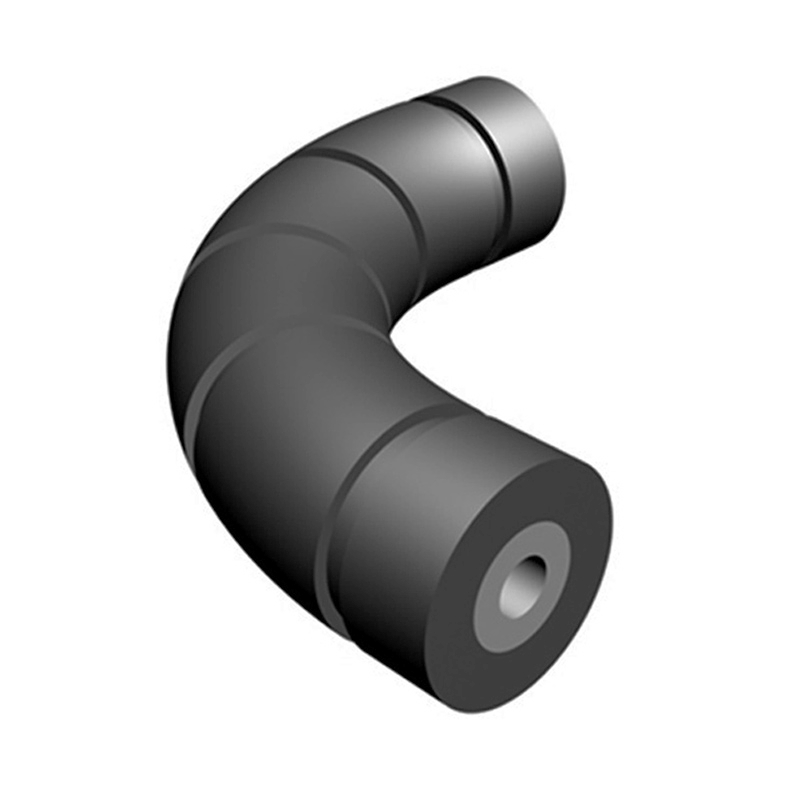

○ HONGRUNTONG Tugboat Fenders are perfect for this zone. They provide resilient protection, ensuring that the stern remains safe during docking operations.

Corners and pilings present unique challenges. These areas can be prone to wear and tear due to their geometry and the forces exerted during docking.

● Risks Associated: Corners often experience concentrated impacts, while pilings can be struck by vessels at awkward angles, leading to damage.

● Effective Fender Strategies:

○ Utilizing HONGRUNTONG Composite Fenders can significantly reduce friction and impact forces at these critical points. Their design helps in protecting against the unique stresses found at corners and around pilings.

Impact Zone | Recommended Fender Type | Key Benefits |

Bow (Front) | HONGRUNTONG Cone Fenders | Stability under angular loads |

Midship (Sides) | HONGRUNTONG Element Fenders | High energy absorption |

Stern (Rear) | HONGRUNTONG Tugboat Fenders | Resilient protection |

Corners and Pilings | HONGRUNTONG Composite Fenders | Reduced friction and impact forces |

By understanding and identifying these impact zones, you can implement effective dock protection strategies. This proactive approach not only safeguards your assets but also enhances operational efficiency.

Selecting the right fender type is essential for effective dock protection. Each fender type is designed to address specific impact zones, ensuring that both vessels and docks remain safe during docking operations. Below, we’ll explore various fender types, their unique characteristics, and applications.

Fenders play a crucial role in absorbing the energy generated when vessels make contact with the dock. Choosing the appropriate fender type can significantly mitigate damage and enhance safety. Here are some important considerations:

● Impact Zones: Different fender types are tailored to protect specific impact zones, such as the bow, midship, and stern areas of a vessel.

● Material and Design: The choice of material affects durability, performance, and maintenance needs. Various designs cater to different docking scenarios, from heavy-duty industrial use to recreational boating.

Let’s dive deeper into each fender type, highlighting their features, benefits, and typical applications.

● Features and Benefits: Cell fenders are cylindrical and designed to absorb high energy from heavy impacts. Their robust construction allows them to withstand substantial forces while maintaining structural integrity.

● Typical Applications: These fenders are commonly used in heavy-duty docks, container terminals, and areas where large vessels operate. They are ideal for high-traffic ports, ensuring maximum protection against frequent impacts.

● Characteristics: Cone fenders have a tapered shape that allows for efficient energy absorption. This design helps distribute impact forces evenly, reducing stress on both the fender and the dock.

● Use Cases: Particularly effective in offshore platforms, cone fenders are built to endure harsh marine environments. They are also suitable for commercial docks where larger vessels frequently dock.

● Advantages: Arch fenders provide excellent energy absorption and flexibility. Their curved shape allows them to adapt to various vessel sizes and docking angles, making them versatile for different scenarios.

● Ideal Scenarios: These fenders are perfect for marinas and small ports, where space is often limited. They offer reliable protection without occupying excessive space, making them a popular choice for recreational boating facilities.

● Basic Protection: Cylindrical fenders are straightforward in design, offering essential protection during docking. They are durable and can handle moderate impacts effectively.

● Common Applications: Suitable for general berths and smaller ports, cylindrical fenders are often used in locations where vessels require basic protection without complex installation.

● Continuous Profile Advantages: Extruded fenders feature a continuous profile, which helps distribute impact forces evenly across the fender. This design minimizes localized stress points, enhancing durability.

● Applications: Widely used for bridge piers and straight quay walls, they provide consistent protection along the length of the docking area. Their adaptability makes them suitable for various docking configurations.

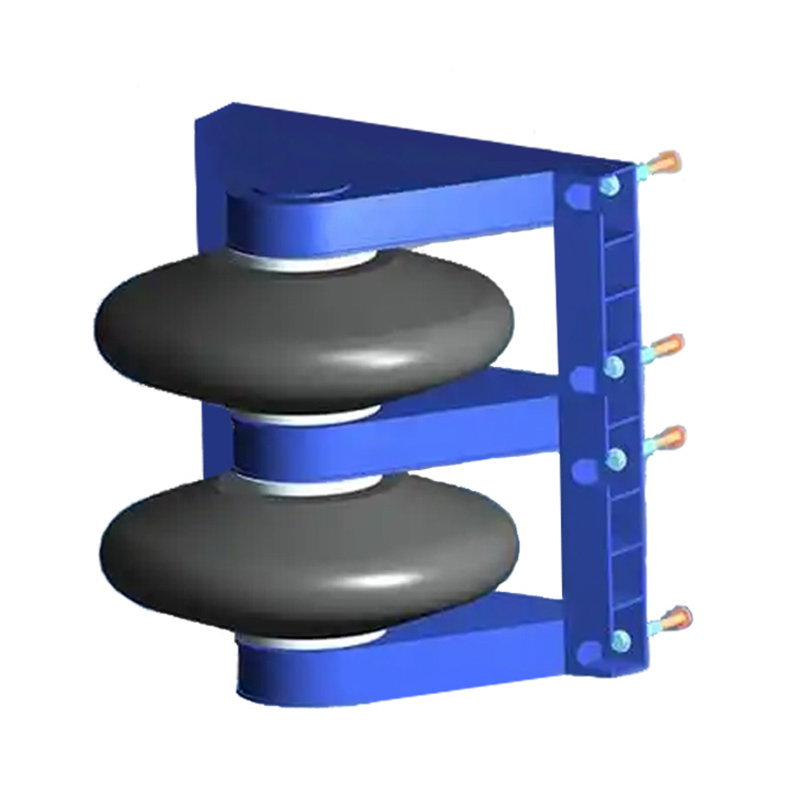

● Modular Design: Element fenders are versatile and can be customized based on specific needs. Their modular design allows for easy installation and replacement, making maintenance straightforward.

● Energy Absorption Capabilities: Ideal for industrial docks, element fenders effectively absorb energy from various vessel sizes. They are particularly useful in environments where different types of vessels dock regularly.

● Low Friction Features: Composite fenders are designed to reduce friction, which minimizes wear and tear on both the fender and the vessel. This feature extends the lifespan of both the fender and the dock.

● Suitable Applications: Commonly used in commercial docks, composite fenders are effective in high-traffic areas where vessels frequently come into contact with the dock.

● Resilience: Tugboat fenders are built to withstand high-impact contact zones. Their robust construction ensures they can handle the rigors of tugboat operations, where quick maneuvers and strong forces are common.

● Specific Use Cases: These fenders are essential for tugboats, which often face challenging docking situations. Their design allows for effective protection during towing and maneuvering operations.

● Rotating Design Benefits: Roller fenders have a unique rotating mechanism that helps absorb impact while allowing for smooth movement. This design reduces friction and wear on both the fender and the dock.

● Applications: Particularly useful for curved dock entries, roller fenders provide flexibility and adaptability. They are ideal for facilities where vessels need to navigate tight spaces.

Fender Type | Key Features | Typical Applications |

Cell Fender | High energy absorption | Heavy-duty docks, container terminals |

Cone Fender | Stability under angular loads | Offshore platforms |

Arch Fender | Excellent energy absorption | Marinas, small ports |

Cylindrical Fender | Basic protection | General berths |

Extruded Fender | Continuous profile | Bridge piers, straight quay walls |

Element Fender | Modular design | Industrial docks |

Composite Fender | Low friction | Commercial docks |

Tugboat Fender | Resilient for high-impact zones | Tugboats |

Roller Fender | Rotating design | Curved dock entries |

By understanding the various types of fenders and their applications, you can make informed decisions about dock protection. This knowledge helps ensure the safety and longevity of your docking operations, ultimately leading to smoother and more efficient marine activities.

Effective fender placement is crucial for ensuring optimal dock protection. The right strategies can minimize damage during docking and enhance the overall safety of marine operations. Here, we’ll explore core principles and specific placement strategies tailored to different impact zones.

When it comes to fender placement, several core rules guide the process:

● Assess Vessel Size: Understanding the size and type of vessels that will dock is essential. Larger vessels require more robust fenders and strategic placement to absorb higher impacts.

● Consider Dock Type: Different dock configurations (straight, curved, floating) necessitate unique placement strategies. Aligning fender types with dock characteristics ensures effective protection.

● Height and Alignment: Fenders should be positioned at appropriate heights to match the vessel’s points of contact. Proper alignment ensures maximum energy absorption during docking.

Continuous straight walls are common in many docks. These areas require fenders that provide uninterrupted protection.

● Characteristics: The impact forces are uniform along the wall, making it essential to have fenders that cover the entire length.

● Recommended Fender Combinations:

○ HONGRUNTONG Extruded Fenders provide continuous profile coverage, while Element Fenders offer modular flexibility. Together, they create a comprehensive protection system that effectively absorbs impacts.

Curved docks present unique challenges due to their geometry and the movement of vessels.

● Unique Challenges: Vessels may not align perfectly with the fender line, leading to uneven impact forces. This requires a flexible solution to accommodate varying angles.

● Fender Strategies:

○ Utilizing HONGRUNTONG Roller Fenders is ideal here. Their low-friction design allows for smooth movement along the curve, reducing wear and tear while ensuring effective protection.

Certain areas of a dock experience heavy-duty impacts, necessitating robust fender solutions.

● Recommended Fender Types:

○ HONGRUNTONG Cell Fenders are perfect for absorbing high energy impacts.

○ Tugboat Fenders are designed specifically for high-impact zones, providing resilience against frequent and forceful contact.

● Installation Strategies: Position these fenders at critical contact points to maximize protection during high-impact situations.

Docks near tidal areas face varying water levels, which can complicate fender placement.

● Considerations: It's essential to adjust fender heights based on tidal fluctuations to maintain effective protection throughout changing conditions.

● Fender Adjustments:

○ HONGRUNTONG Arch Fenders are an economical choice here. Their design allows for effective energy absorption while accommodating changes in water levels.

For small to medium berths, cost-effective solutions are vital.

● Cost-Effective Fender Solutions:

○ HONGRUNTONG Cylindrical Fenders provide basic protection without breaking the bank.

○ Arch Fenders are also suitable for these areas, offering reliable performance at a lower cost.

Impact Zone | Recommended Fender Types | Key Features |

Continuous Straight Wall | HONGRUNTONG Extruded & Element Fenders | Continuous coverage, modular design |

Curved/Moving Structure | HONGRUNTONG Roller Fenders | Low-friction, adaptable to curves |

High-Impact Contact Zones | HONGRUNTONG Cell & Tugboat Fenders | High energy absorption, resilient |

Tidal/Fluctuating Water Levels | HONGRUNTONG Arch Fenders | Economical, adjustable for water levels |

General Berthing | HONGRUNTONG Cylindrical & Arch Fenders | Cost-effective, reliable protection |

By implementing these fender placement strategies, you can enhance dock protection and ensure the safety of both vessels and infrastructure. Tailoring your approach to the specific impact zones will lead to more efficient and effective docking operations.

Dock protection is essential for safeguarding vessels and infrastructure. Proper fender placement minimizes damage during docking operations.

Implementing effective dock protection strategies is crucial for operational efficiency.

For tailored dock protection solutions, consult with HONGRUNTONG to enhance your docking safety and efficiency.